Decaffeination

Decaffeination is the act of removing caffeine from coffee beans, cocoa, tea leaves and other caffeine-containing materials. (While caffeine-free soft drinks are occasionally referred to as “decaffeinated”, some are better termed “uncaffeinated”: prepared without adding caffeine during production.) Despite removal of most caffeine, many decaffeinated drinks still have around 1–2% of the original caffeine remaining in them, and research has found that certain decaffeinated coffee drinks can contain around 20% of the original caffeine.

In the case of coffee, various methods can be used. The process is usually performed on unroasted (green) beans, and starts with steaming of the beans. They are then rinsed with a solvent that extracts the caffeine while leaving the other essential chemicals in the coffee beans. The process is repeated anywhere from 8 to 12 times until it meets either the international standard of having removed 97% of the caffeine in the beans or the EU standard of having the beans 99.9% caffeine-free by mass. Coffee contains over 400 chemicals important to the taste and aroma of the final drink: It is, therefore, challenging to remove only caffeine while leaving the other chemicals at their original concentrations. Coffea arabica normally contains about half the caffeine of Coffea robusta. A Coffea arabica bean containing little caffeine was discovered in Ethiopia in 2004.

Processes:

The Roselius process: The first commercially successful decaffeination process was invented by Ludwig Roselius and co-workers in 1903 and patented a few years later. It involved steaming coffee beans with various acids or bases then using benzene as a solvent to remove the caffeine. Coffee decaffeinated this way was sold as Kaffee HAG after the company name Kaffee Handels-Aktien-Gesellschaft (Coffee Trading Company) in most of Europe, as Café Sanka (from “sans caffeine”) in France and later as Sanka brand coffee in the U.S. Café HAG and Sanka are now worldwide brands of Kraft Foods. Due to health concerns regarding benzene, this process is no longer used commercially and Coffee Hag and Sanka are produced using a different process.

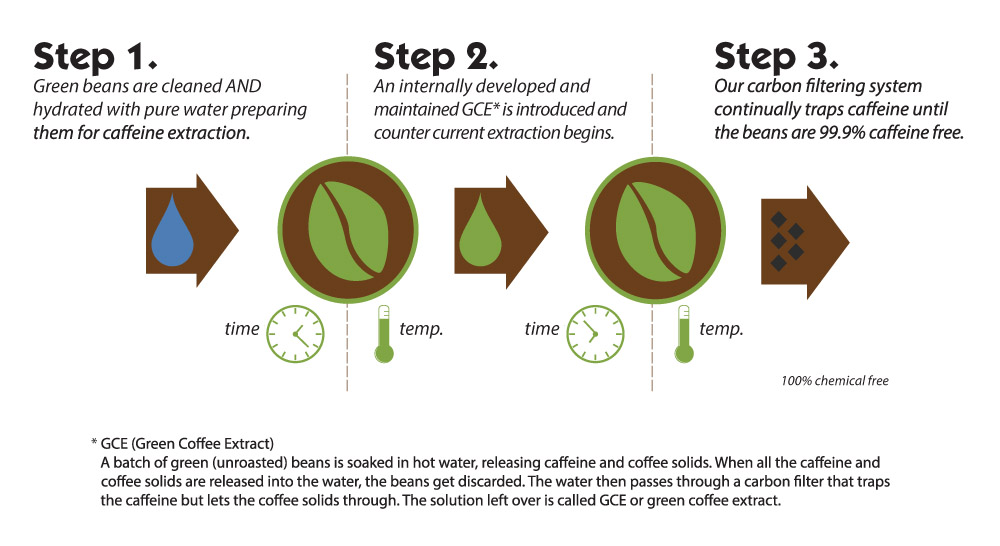

Swiss Water process: The use of water as the solvent to decaffeinate coffee was originally developed in Switzerland in the 1980s and is now used commercially under the trade-mark “Swiss Water Process” by The Swiss Water Decaffeinated Coffee Company of Burnaby, British Columbia, Canada. They describe it as a “chemical free” process. Green coffee beans can be immersed in water to extract their caffeine but this will also extract desirable oils and other solids from the bean resulting in less flavourful brewed coffee. The Swiss Water process method attempts to overcome this difficulty by using water saturated with these desirable coffee components thus reducing or eliminating their extraction during the decaffeination process.

Water saturated in this way is referred to as green coffee extract or GCE. It is created using a separate batch of green coffee beans that are immersed in water and then discarded. The GCE is then filtered to remove only the caffeine from it. A fresh batch of green coffee beans, are then immersed in the GCE to remove caffeine but retain other components. The process of filtering the GCE to remove caffeine and immersing the beans is repeated until the beans are 99.9% caffeine free by mass. This process takes 8 to 10 hours.

Direct method/Natural Decaffeination: In the direct method, the coffee beans are first steamed for 30 minutes and then repeatedly rinsed with either dichloromethane or ethyl acetate for about 10 hours. The solvent is then drained away and the beans steamed for an additional 10 hours to remove residual solvent. Sometimes coffees that are decaffeinated using ethyl acetate are referred to as naturally processed, because ethyl acetate can be derived from various fruits or vegetables, but because of the impracticality of gathering natural ethyl acetate, the ethyl acetate used for decaffeination is synthetic.

Indirect method/KVWMethod: In the indirect method, beans are first soaked in hot water for several hours, in essence making a strong pot of coffee. Then the beans are removed and either dichloromethane or ethyl acetate is used to extract the caffeine from the water. As in other methods, the caffeine can then be separated from the organic solvent by simple evaporation. The same water is recycled through this two-step process with new batches of beans. An equilibrium is reached after several cycles; wherein the water and the beans have a similar composition except for the caffeine. After this point, the caffeine is the only material removed from the beans, so no coffee strength or other flavourings are lost. Because water is used in the initial phase of this process, sometimes indirect method decaffeination is referred to as “water-processed”. In this process, the coffee beans are soaked in hot water to extract much of the caffeine from the beans. The beans are removed from the water and then the methylene chloride solvent is added to bond with the caffeine. After the methylene chloride/caffeine compound is skimmed from the surface of the mixture, the beans are returned to reabsorb the liquid. The KVW method of decaffeination removes between 96 to 97% of caffeine from a batch of coffee.

The KVW method is also referred to as MC (methylene chloride).

CO2 process: This process is technically known as supercritical fluid extraction. Pre-steamed beans are immersed in supercritical carbon dioxide in a pressure chamber at 73 to 300 atmospheres. After a thorough soaking for around ten hours, the pressurized CO2 containing dissolved caffeine is removed from the chamber which is returned to atmospheric pressure, allowing the CO2 to evaporate. The caffeine is removed from the CO2 using charcoal filters and the CO2 is recycled for use on another batch of beans. This process has the advantage that it avoids the use of potentially harmful substances.

Green coffee beans are soaked in a hot water/coffee solution to draw the caffeine to the surface of the beans. Next, the beans are transferred to another container and immersed in coffee oils that were obtained from spent coffee grounds. After several hours of high temperatures, the triglycerides in the oils remove the caffeine — but not the flavor elements — from the beans. The beans are separated from the oils and dried. The caffeine is removed from the oils, which are reused to decaffeinate another batch of beans. This is a direct-contact method of decaffeination.

Decaffito: As of 2009, progress toward growing coffee beans that do not contain caffeine was still continuing. The term “Decaffito” has been coined to describe this type of decaffeinated coffee, and trademarked in Brazil. The term ‘decaffito’ is composed of ‘decaf’ and the suffix ‘fito’ (from Greek phyto) signifying plant or vegetable. Thus ‘decaffito’ is decaf naturally grown on the coffee plant. Moreover, ‘decaffito™’is a trademark of Brazil. The prospect for Decaffito type coffees was shown by the discovery of the naturally caffeine-free Coffea charrieriana, reported in 2004. It has a deficient caffeine synthase gene, leading it to accumulate theobromine instead of converting it to caffeine. Either this trait could be bred into other coffee plants by crossing them with C. charrieriana or an equivalent effect could be achieved by knocking out the gene for caffeine synthase in normal coffee plants.

Solvent-based processes

KVW (Methylene Chloride)

Natural decaffeination (Ethyl Acetate)

Mountain Water Process (Methylene Chloride)

Non-solvent processes

Carbon Dioxide Process

Swiss Water Process

Source: Wikipedia, the free encyclopedia